Welcome to Our Company!

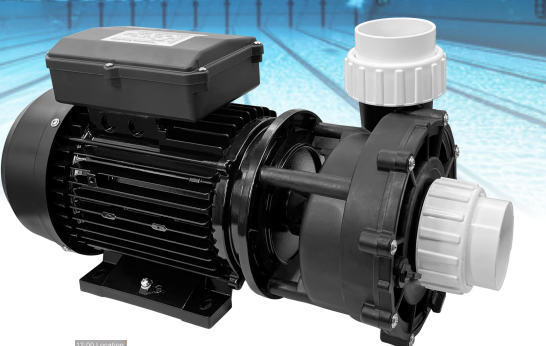

JET PUMP

41990 INR/Piece

Product Details:

- Type Jet Pump

- Application Water Lifting

- Color Blue

- Material Cast Iron

- Shape Horizontal

- Size Standard

- Power Supply Electric

- Click to View more

X

JET PUMP Price And Quantity

- 41990 INR/Piece

- 1 to bulks Piece

JET PUMP Product Specifications

- Water Lifting

- Cast Iron

- Blue

- Electric

- Industrial and Agricultural

- Standard

- Jet Pump

- Horizontal

Product Description

PJ series water circulation pump provides large flow and are highly efficient. It is mainly used for counter current system, water circulation and commercial spa. It is built with heavy duty body to last longer and is flowing water proof standard and build in thermal protection.

Features

Class insulation 155(F)

Low noise level

Build in Thermal protection

Complete separation of water and the shaft, safe and reliable

High quality wear resistant mechanical seal

IP55 waterproof standard

Material

Pump Body Polypropylene+30% Fiberglass

Shaft 45# steel nickel-plated

Mechanical Sea Ceramic/Carbon/Viton/SUS304

Impellar and diffuses NORYL-GFN20-801

Motor COPPER

Industrial-Grade Build Quality

Constructed from durable cast iron and coated with anti-corrosive paint, these jet pumps withstand harsh environments, ensuring a long lifespan and minimal maintenance. Their robust build makes them suitable for heavy-duty industrial and agricultural operations.

Efficient Performance & Versatility

Delivering a flow rate of up to 40 liters per minute and head up to 70 meters, these pumps efficiently handle varying water lifting tasks. The efficient air-cooled motor and precision brass impeller provide smooth operation and high reliability in diverse applications.

Wide Application Scope

These jet pumps serve both industrial and agricultural needs, including irrigation, water transfer, and distribution systems. Their flexible configuration supports single or three-phase power input with standard voltage and frequency requirements to suit various installation environments.

FAQs of JET PUMP:

Q: How does the jet pump operate for water lifting applications?

A: The jet pump works by using a high-speed motor to drive a brass impeller, creating suction that draws water from wells or tanks. It then pushes the water to the desired height, making it suitable for lifting water up to 70 meters for irrigation or supply systems.Q: What are the main benefits of using a jet pump with anti-corrosive coating and brass impeller?

A: The anti-corrosive paint protects the cast iron body from rust and damage, while the brass impeller ensures smooth water flow and resists wear. This combination enhances durability, efficiency, and lifespan, especially in demanding industrial and agricultural environments.Q: When should I choose a single-phase versus a three-phase jet pump?

A: Single-phase jet pumps are ideal for smaller operations or locations with standard residential power supply. For larger or continuous applications in industrial or agricultural settings where higher efficiency and reliability are required, a three-phase pump is recommended.Q: Where is the ideal installation location for this jet pump?

A: This pump is designed for base-mounted installation in horizontal orientation. It is suitable for both indoor and outdoor setups (with suitable protective measures), at locations with electric power access, such as agricultural fields, industrial plants, or water distribution centers.Q: What is the standard process for installing and operating the jet pump?

A: Begin by securely mounting the pump on a stable base and ensuring the inlet and outlet connections (25x25 mm) are properly attached. Fill the pump casing with water to prime it, connect to the power supply within 220-240V AC range, and switch on. Regular maintenance entails inspecting for leaks, and cleaning to ensure optimal performance.Q: How can this jet pump be used in agricultural irrigation systems?

A: In agriculture, the jet pump efficiently lifts water from storage tanks, wells, or rivers to provide consistent irrigation for crops. With its high flow rate and ability to generate significant pressure, it enables even water distribution across large fields.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send SMS

Send SMS